For our bipropellant rocket, we aim to find tanks and the bottom and top parts of the enclosed tank that match our required pressure, stress, and weight ranges. This is tough considering there are so many variables at play, but we can do our best and try to get the values as accurately as possible. I just worked on writing a paper to calculate the required bulkhead thickness (the so called bottom and top “lids” of the tank), which are bolted to the cylindrical tank.

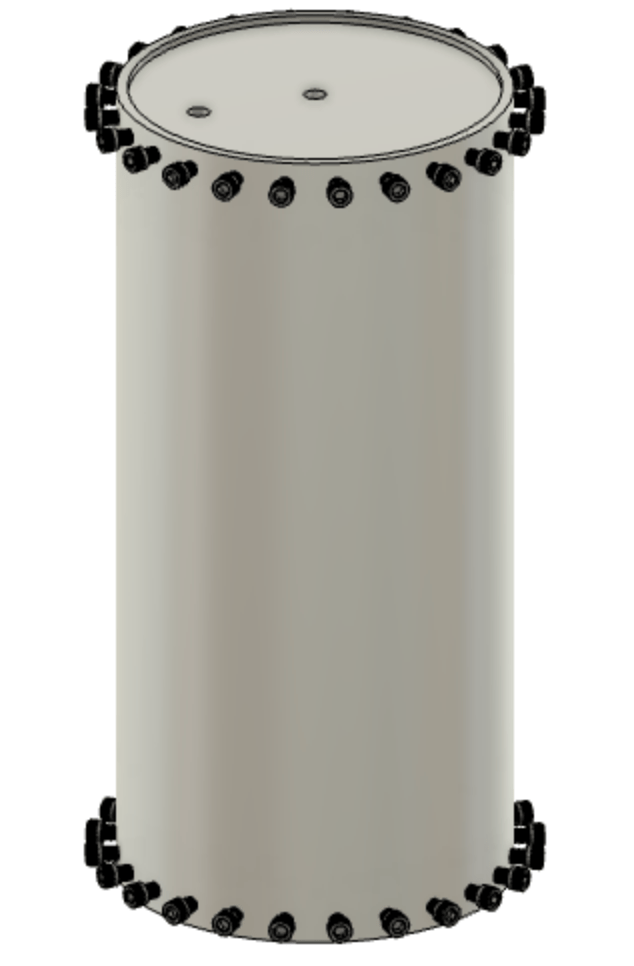

This what a sample tank looks like (above is a 3D design done on Fusion 360 by our propulsion team). Attached below is my paper outlining what thickness is required for the top and bottom bulkhead, which all said and done, are pretty conservative and safe values. But after all, we don’t want anything exploding.